Lead screws can be found in nearly every industry as they are one of the most basic linear electric actuator technologies available. In terms of matching cost with reliability, lead screws are notable components and can be found in quality electric linear actuators at affordable prices. In this article, we will cover the top 10 lead screw questions we frequently get asked which you will find useful to better understand lead screws and how they are used in electric linear actuators.

1. What Is a Lead Screw?

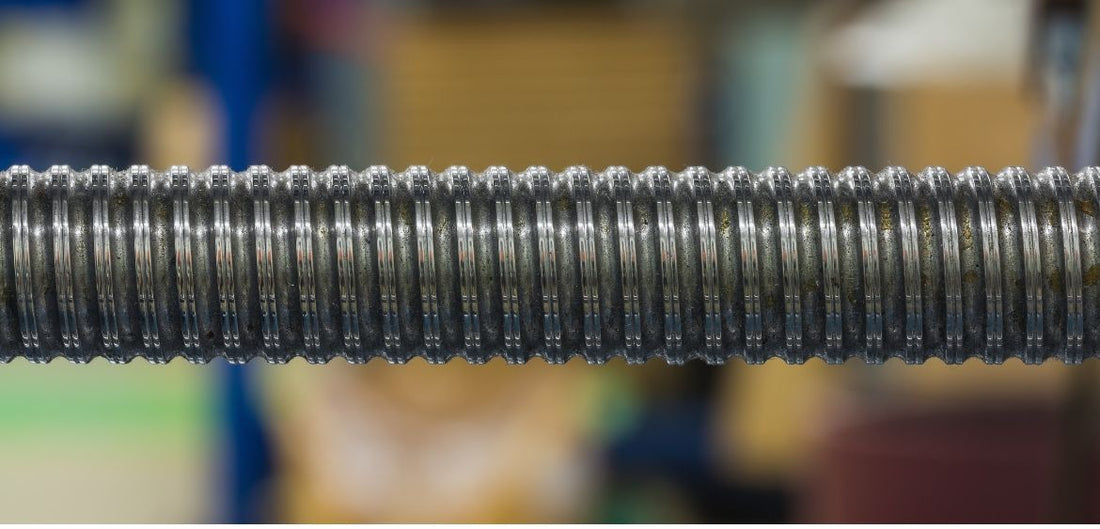

A lead screw is any threaded screw that helps create motion by moving a load along its surface. In the case of actuators, lead screws are used to push and pull the stroke.

Lead screws come in a variety of lengths and thicknesses. The length and thickness of each will determine how long the stroke of your actuator is and how fast it will move. The thicker the lead screw, the slower its travel speed.

2. What Is an Acme Screw?

An ACME screw is a specific type of lead screw that is of the trapezoidal thread form. So, if we were to get out a magnifying glass and look closely, we'll see that the outline of the threads on the screw form a trapezoid with a 29° angle. ACME screws are the most common form of lead screw used in the industry.

3. What's the Advantage of a Lead Screw?

In terms of cost, you're not going to find anything better than lead screws. This is because a high lead screw force is possible to handle heavy loads while still offering high precision and repeatability at the same time. Lead screw vibrations will occur in very small amounts in every application, but this is generally not a problem for most application.

4. Can a Lead Screw Bend?

It is possible for a lead screw to bend under certain conditions. A long lead screw has a greater risk of bending when compared to lead screws of a shorter length. If a long lead screw is used correctly within the lead screw force ratings and follows the manufacturer's specifications, there should not be any issues with bending. Calculating the required force of an actuator helps determine approximately what operating forces were required before selecting an actuator with lead screws.

5. Do Lead Screws Experience Back Driving?

Back driving will mainly depend on the lead screw’s efficiency. Lead screws will not experience back driving when the following 2 requirements are met:

- The screw efficiency is below 40%

- There is no vibration experienced by the screw

6. What Materials Are Used to Manufacture Lead Screws?

As there are many different materials that could be used to manufacture lead screws, the most suitable material will depend on what the lead screw is being used for as well as your application’s priorities and requirements. Materials such as carbon steel, stainless steel, titanium, aluminum, bronze, ceramic, and plastic materials have been used for manufacturing lead screws.

7. What Makes a Lead Screw Efficient?

Whenever you hear the word 'efficiency' being tossed around with lead screws, the main factor is friction. For a lead screw to convert rotary motion into linear motion, it needs to overcome friction. To improve lead screw efficiency, increasing the angle of the lead screw’s thread helps reduce the amount of energy required to overcome friction.

8. Where Are Lead Screws Used?

We have seen a lead screw used for many different applications in various industries. Any place where smooth, reliable motion is required, a lead screw actuator can handle the task. This can include automotive applications, home automation, robotics, manufacturing, and many more areas with emerging technologies.

9. Do I Need to Lubricate My Lead Screws?

The electric linear actuators we offer have lead screws that are self-lubricated internally for the life of the unit and require no future lubrication when used within their ratings.

10. Can I Use Lead Screws in Harsh Environments?

Lead screws are particularly useful in harsh environments because they have no extra rolling parts. Whenever actuators with rolling components are used in environments with dust or debris present, the risk of the particles accumulating at the rollers may result in decreasing performance. Lead screw actuators are better suited at withstanding the dust and particles that may be found in harsh environments. The industry uses ingress protection or IP ratings to indicate a product’s ability to withstand liquid and dust intrusion.

In Summary

Lead screws are popular components for electric linear actuators because of the high level of versatility and simplicity they offer at affordable prices. With all the benefits offered from lead screws, it is no wonder they are commonly found in various applications in the industry. If you have any queries or wish to discuss our products further, please do not hesitate in reaching out to us! We are experts in what we do and want to ensure you find the best solution for your application.

sales@progressiveautomations.com | 1-800-676-6123