Les exigences en matière de machines agricoles modernes s'allongent, allant des équipements lourds aux applications d'agriculture de précision. Trouvez les solutions idéales pour vos besoins grâce à notre gamme spécialisée d'actionneurs pour l'agriculture.

Mouvement linéaire spécialement conçu pour l'agriculture et l'élevage.

Conçu pour offrir un mouvement fluide et fiable dans n'importe quel environnement pour les années à venir.

2,41%

Réduction moyenne des coûts d'une année sur l'autre99,8%

Taux de réussite parfait au contrôle qualité100%

Alimenté par les énergies renouvelablesNous sommes plus qu’un fournisseur : nous ajoutons de la valeur au-delà du produit.

Avec un engagement indéfectible envers le succès mutuel, nous sommes un partenaire flexible qui ajoute de la valeur à chaque étape du cycle de vie des composants.

Qualité de produit constamment élevée

Obtenez des taux de défaillance de produits ultra-faibles grâce à un régime de contrôle qualité fiable, rigoureux, adaptatif et systématique.

Progressive Automations est certifié ISO9001.2015

Bénéficiez d'une qualité fiable. Collaborez avec un partenaire véritablement engagé dans l'amélioration continue.

Tarification flexible avec réductions des coûts répercutés

Bénéficiez d'économies grâce à des prix adaptés à la montée en puissance et résistants à l'inflation, où les économies liées à l'échelle vous sont directement répercutées.

Nous livrons à temps, à chaque fois.

Même si les défis de la chaîne d'approvisionnement deviennent de plus en plus courants, nous avons maintenu un taux d'expédition à temps de 98 % depuis 2017.

Délais de livraison nuls et flexibilité inégalée grâce à une logistique intelligente

Évitez les frais de transport aérien coûteux et les retards de production. Nous livrons vos unités personnalisées à votre quai en quelques jours, et non en plusieurs mois.

Les actionneurs linéaires des moissonneuses-batteuses permettent des réglages précis de fonctions telles que la hauteur de la tête de coupe et le positionnement de la bobine, rationalisant ainsi les opérations et améliorant les performances.

Les actionneurs linéaires électriques jouent un rôle essentiel dans les épandeurs agricoles en permettant un contrôle précis des débits de distribution, garantissant ainsi une application uniforme dans les champs. Leur intégration automatise les fonctions clés et intègre des dispositifs de sécurité avancés, améliorant ainsi l'efficacité opérationnelle et la sécurité des pratiques agricoles.

Les actionneurs des pulvérisateurs agricoles assurent une distribution précise du produit, améliorant ainsi la gestion des cultures et réduisant les déchets. Cela améliore la productivité et favorise une agriculture durable en maximisant l'efficacité de la protection des cultures.

Les actionneurs linéaires électriques optimisent les équipements de semis en contrôlant avec précision le placement, la profondeur et l'espacement des graines. Leur intégration simplifie les opérations, réduit les réglages manuels et assure une levée uniforme des cultures, favorisant ainsi des pratiques agricoles plus sûres et plus efficaces.

Les actionneurs linéaires électriques optimisent les presses à balles en ajustant la densité, la tension et les mouvements de la chambre de pressage. Cette automatisation garantit une qualité constante des balles, augmente la fiabilité opérationnelle et réduit le travail manuel, favorisant ainsi des pratiques agricoles plus sûres et plus efficaces.

Les actionneurs linéaires électriques sont essentiels dans l'agriculture verticale, permettant un contrôle précis de l'éclairage, de l'irrigation et des racks verticaux pour optimiser la croissance et le rendement des cultures.

Les actionneurs linéaires permettent un contrôle précis de divers systèmes des véhicules agricoles, garantissant des mouvements efficaces et précis. Cette précision améliore le fonctionnement global des tracteurs et des équipements agricoles, facilitant ainsi l'exécution fluide de diverses tâches agricoles.

Les actionneurs linéaires électriques améliorent la fonctionnalité des machines de récolte en offrant un contrôle précis, une automatisation et des fonctions de sécurité. Leur intégration permet d'accroître la productivité et la sécurité tout en minimisant les besoins en main-d'œuvre.

Les actionneurs linéaires électriques optimisent les andaineurs en ajustant la hauteur de coupe, en contrôlant la vitesse du rabatteur et en gérant la formation des andains. Cette intégration améliore la fiabilité opérationnelle, réduit les interventions manuelles et assure une répartition homogène des cultures, favorisant ainsi des pratiques agricoles plus sûres et plus efficaces.

L'actionneur Progressive Automation a été choisi car il répondait parfaitement aux exigences de vitesse et de charge de notre application. De plus, il utilisait l'énergie électrique plutôt que l'hydraulique, était esthétique et résolvait les problèmes de poids des composants. Un problème de performance majeur est apparu lors de nos longs essais sur le terrain. Ce problème a été résolu facilement, rapidement et sans frais supplémentaires. J'ai apprécié la qualité du produit et le professionnalisme de l'équipe support. C'était une excellente entreprise avec laquelle travailler.

Steve Willey

WILSCOT, LLC

Mouvement linéaire personnalisé pour l'agriculture et l'élevage

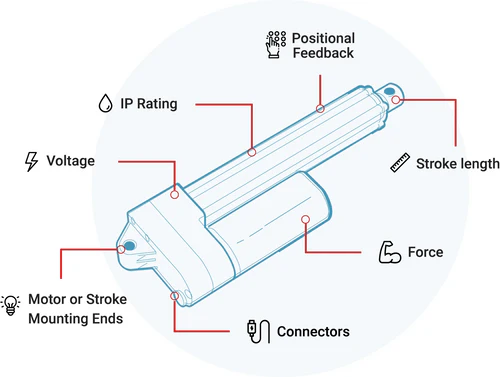

Personnalisation de l'actionneur

Transformez vos projets avec des actionneurs conçus pour répondre à vos défis spécifiques. Que vous soyez en transition depuis l'hydraulique ou confronté à des problèmes tels que les infiltrations d'eau, nous comprenons que chaque application est unique.

Nos ingénieurs vous aident à élaborer des solutions adaptées à vos spécifications exactes, avec des quantités minimales flexibles, transformant des exigences complexes en conceptions précises et efficaces.

À mesure que vos besoins évoluent, nos solutions évoluent également : nous sommes là pour vous accompagner sur le long terme et vous gagnez un partenaire dédié à votre réussite.

Études de cas

Réalisez le projet de vos rêves

Camping-car série Cube

En utilisant des actionneurs linéaires et une technologie de pliage ultra-légère, la série Cube RV vise à offrir des camping-cars légers, compacts et pratiques qui conviennent également aux camionnettes compactes sans sacrifier la durabilité. Dans cette étude de cas, nous aborderons le processus, les défis et les solutions auxquels l'équipe de Cube Series RV a été confrontée pour donner vie à son Cube Series Camper.

Réalisez le projet de vos rêves

Trappe de moteur de bateau

Grâce à des actionneurs linéaires sur mesure de qualité et à des systèmes de contrôle avancés pour la synchronisation, Progressive Automations propose des solutions d'automatisation pratiques, fiables et conviviales permettant aux clients de protéger leurs écoutilles moteur grâce à des panneaux d'écoutille automatisés. Dans cette étude de cas , nous aborderons le processus, les défis et les solutions nécessaires à la mise en œuvre de panneaux d'écoutille automatisés pour bateaux, yachts et autres navires.

DÉCOUVREZ-EN PLUS

Article de blog

Avoiding Actuator Setbacks in Water-Exposed Installations

Article de blog

Actionneurs électriques : révolutionner l'automatisation industrielle au-delà des vérins hydrauliques

Article de blog

Téléchargez le guide de test

Ce guide décrit les étapes essentielles et le processus d'évaluation d'un actionneur. Une liste de contrôle est incluse pour garantir le respect de toutes les exigences.

Article de blog

Top 10 des questions que nous posent nos clients OEM

Vous trouverez des FAQ utiles de la part des clients OEM pour votre recherche d'un fournisseur de pièces d'actionneurs linéaires électriques .

Application

Moissonneuses-batteuses et ensileuses

Les actionneurs des moissonneuses permettent des réglages précis de fonctions telles que les réglages du bec verseur et le positionnement du moulinet, rationalisant ainsi les opérations et améliorant les performances.

Défis

Les actionneurs linéaires électriques des moissonneuses-batteuses sont exposés aux conditions environnementales, à la manutention de charges lourdes, à une maintenance de précision, aux exigences d'alimentation électrique et à la complexité d'intégration. La poussière, l'humidité et les fluctuations de température peuvent dégrader les performances. Les charges lourdes augmentent les contraintes mécaniques, et le maintien de la précision est difficile en raison de l'usure et des dérives d'étalonnage.

Solutions

Protégez vos actionneurs des intempéries grâce à des boîtiers et des joints IP. Utilisez des matériaux robustes pour la manutention de charges lourdes et des capteurs haute résolution pour une précision optimale. Optimisez la gestion de l'énergie grâce à des moteurs et des algorithmes performants. Assurez la compatibilité avec les protocoles des machines agricoles et fournissez une documentation et des tests complets pour une intégration fluide.

Avantages

Les actionneurs linéaires électriques optimisent les moissonneuses-batteuses et ensileuses en offrant un contrôle précis, une meilleure efficacité énergétique et une maintenance réduite. Leur conception compacte améliore la maniabilité, tandis que leur intégration aux systèmes d'automatisation et leur impact environnemental réduit s'inscrivent dans les objectifs modernes de l'agriculture et du développement durable.

Actionneur linéaire résistant à l'eau IP66 - Rétroaction en option

Voir le cas d'utilisation Voir le produit

Actionneur linéaire résistant à l'eau IP66 - Rétroaction en option

Voir le cas d'utilisation Voir le produitMoissonneuses-batteuses et ensileuses

Positionnement de la bobine

Modèle

Actionneur linéaire PA-13

Fonction

Les actionneurs s'étendent et se rétractent pour ajuster le positionnement de la bobine en fonction de la hauteur des cultures.

Avantages

Permet un transfert efficace de la récolte de la tête de coupe au mécanisme de battage de la moissonneuse. Cette précision minimise les pertes de récolte et améliore l'efficacité globale du processus de récolte.

Actionneur linéaire PA-13

L'actionneur linéaire industriel haute force PA-13 est l'une des unités les plus puissantes de notre gamme.

Caractéristiques principales

- Capacité de charge élevée

- Caractéristiques de protection/sécurité

- Sans entretien

- Construction durable

- Protection contre l'eau IP66

Moissonneuses-batteuses et ensileuses

Réglage du bec verseur

Modèle

Actionneur linéaire PA-10

Fonction

Régule le rejet des résidus de culture, contribuant ainsi à des pratiques de gestion efficaces des champs.

Avantages

Un réglage correct du bec verseur permet une répartition uniforme des résidus, ce qui contribue à la conservation du sol et réduit le besoin de défrichage supplémentaire du champ.

Actionneur linéaire PA-10

Le PA-10 est un actionneur étanche hautement efficace conçu pour une large gamme d'applications, y compris les équipements agricoles.

Caractéristiques principales

- Personnalisations du capteur à effet Hall

- Taille compacte

- Rapport performance/taille élevé

- Sans entretien

- Faible bruit

- Protection étanche IP68M

Demander des spécifications personnalisées

Demander des spécifications personnalisées

Combine & Forage Harvesters

Reel Positioning

Model

PA-HD3 Ultra High Force Industrial Linear Actuator

Function

Actuators extend and retract to adjust the positioning of the reel according to the height of the crops.

Benefits

Allows for efficient transfer of harvested crop material from the header to the threshing mechanism within the harvester. This precision minimizes crop loss and enhances the overall efficiency of the harvesting process.

PA-HD3 Ultra High Force Industrial Linear Actuator

The PA-HD3 Ultra High Force Industrial Linear Actuator delivers powerful force, smooth motion, and dependable performance for demanding industrial applications. Designed with a ball screw mechanism and static waterproof protection, it ensures long-lasting durability even in harsh environments.

Key Features

- High Load Capacity (up to 3822 lbs push / 4496 lbs hold)

- IP67 Water and Dust Protection

- Ball Screw Design for Smooth, Efficient Motion

- Durable Stainless Steel Shaft and Metal Gears

- Manual Override Function for Power Loss Situations

- Electrical Overload Protection (25A)

Request Custom Specs

Application

Pulvérisateurs

Les actionneurs des pulvérisateurs agricoles assurent une distribution précise du produit, améliorant ainsi la gestion des cultures et réduisant les déchets. Cela améliore la productivité et favorise une agriculture durable en maximisant l'efficacité de la protection des cultures.

Défis

Les pulvérisateurs agricoles sont confrontés à de nombreux défis liés aux actionneurs linéaires, notamment la corrosion due aux produits chimiques, les vibrations et les chocs dus aux terrains accidentés, les variations extrêmes de température, la contamination par la poussière et les débris, et la nécessité d'un fonctionnement à haute pression. Ces problèmes peuvent compromettre la fonctionnalité, la durabilité et les performances des actionneurs.

Solutions

Pour relever ces défis, utilisez des matériaux résistants à la corrosion comme l'acier inoxydable ou l'aluminium, concevez des structures robustes dotées de propriétés d'absorption des chocs, intégrez des composants résistants à la température et une gestion thermique optimale. Utilisez des mécanismes d'étanchéité efficaces et des joints résistants aux pressions élevées. Un entretien et des tests réguliers garantissent la fiabilité et des performances optimales dans diverses conditions de fonctionnement.

Avantages

Les actionneurs linéaires électriques sont essentiels aux pulvérisateurs agricoles grâce à leur précision de contrôle, leur efficacité, leur adaptabilité et leur faible maintenance. Ils offrent un fonctionnement silencieux, une efficacité énergétique optimale, une télécommande, une durabilité, des fonctions de sécurité et des performances constantes, permettant ainsi d'optimiser les schémas de pulvérisation et de mieux gérer les cultures.

Pulvérisateurs

Contrôle de la hauteur de la flèche

Modèle

Actionneur linéaire PA-13

Fonction

Les actionneurs linéaires électriques maintiennent une hauteur de rampe constante pendant les opérations de pulvérisation

Avantages

En ajustant l'élévation de la rampe du pulvérisateur, ces actionneurs assurent une distance optimale entre la buse et la cible, minimisant ainsi la dérive et maximisant l'efficacité de la pulvérisation sur des terrains variés. Ce contrôle précis améliore la protection des cultures tout en réduisant l'impact environnemental.

Actionneur linéaire PA-13

L'actionneur linéaire industriel haute force PA-13 est l'une des unités les plus puissantes de notre gamme.

Caractéristiques principales

- Capacité de charge élevée

- Caractéristiques de protection/sécurité

- Sans entretien

- Construction durable

- Protection contre l'eau IP66

Pulvérisateurs

Réglage du motif de pulvérisation

Modèle

Actionneur linéaire PA-01

Fonction

Les actionneurs linéaires électriques s'étendent et se rétractent pour permettre un contrôle dynamique des modèles de pulvérisation.

Avantages

Les opérateurs peuvent s'adapter aux variations des conditions de culture et de la densité du couvert végétal en ajustant l'angle et l'orientation des buses de pulvérisation. Cette optimisation maximise la couverture et la pénétration, améliorant ainsi l'efficacité des applications agrochimiques tout en minimisant les pertes.

Actionneur linéaire PA-01

De taille compacte avec des capacités de force moyennes, l'actionneur linéaire PA-01 a une faible consommation de courant idéale pour l'efficacité énergétique.

Caractéristiques principales

- Personnalisations du capteur à effet Hall

- Taille compacte

- Rapport performance/taille élevé

- Sans entretien

- Faible bruit

- Protection contre l'eau IP65

Demander des spécifications personnalisées

Demander des spécifications personnalisées

Application

Presses à balles

Les actionneurs linéaires électriques optimisent les presses à balles en ajustant la densité, la tension et les mouvements de la chambre de pressage. Cette automatisation garantit une qualité constante des balles, augmente la fiabilité opérationnelle et réduit le travail manuel, favorisant ainsi des pratiques agricoles plus sûres et plus efficaces.

Défis

Les actionneurs linéaires électriques des presses agricoles sont confrontés à des problèmes tels que la pénétration de poussière et de débris, l'exposition à l'humidité, la manutention de charges lourdes, les températures extrêmes, les vibrations et les chocs, ainsi que la fiabilité de l'alimentation électrique. Ces difficultés peuvent impacter les performances, la fiabilité et la longévité.

Solutions

Pour relever ces défis, nous utilisons des conceptions étanches avec boîtiers de protection, matériaux résistants à la corrosion, composants de haute qualité, matériaux thermorésistants, mécanismes d'absorption des chocs et solutions d'alimentation de secours. Ces mesures garantissent des performances et une durabilité optimales dans des conditions agricoles difficiles.

Avantages

Les actionneurs linéaires électriques améliorent la précision du contrôle des presses agricoles, garantissant une taille et une densité de balles constantes. Ils automatisent les fonctions essentielles, augmentant ainsi l'efficacité et réduisant le travail manuel. Les dispositifs de sécurité atténuent les risques mécaniques, tandis que la fiabilité, l'efficacité énergétique et la faible maintenance contribuent à améliorer les performances globales et le confort de l'opérateur.

Presses à balles

Positionnement et mouvement

Modèle

Actionneur linéaire PA-13

Fonction

Ces actionneurs assurent un positionnement précis et un mouvement contrôlé de divers composants à l'intérieur de la presse.

Avantages

Améliore l'efficacité des opérations de pressage en assurant un alignement précis des matériaux et un mouvement contrôlé des portes de la chambre. Ce contrôle précis minimise les bourrages et les dysfonctionnements, pour un fonctionnement plus fluide et des temps d'arrêt réduits.

Actionneur linéaire PA-13

L'actionneur linéaire industriel haute force PA-13 est l'une des unités les plus puissantes de notre gamme.

Caractéristiques principales

- Capacité de charge élevée

- Caractéristiques de protection/sécurité

- Sans entretien

- Construction durable

- Protection contre l'eau IP66

Demander des spécifications personnalisées

Balers

Positioning and Movement

Model

PA-HD3 Ultra High Force Industrial Linear Actuator

Function

These actuators provide precise positioning and controlled movement of various components within the baler.

Benefits

Enhances the effectiveness of baling operations by ensuring accurate alignment of materials and controlled movement of chamber doors. This precise control minimizes jams and malfunctions, leading to smoother operation and reduced downtime.

PA-HD3 Ultra High Force Industrial Linear Actuator

The PA-HD3 Ultra High Force Industrial Linear Actuator delivers powerful force, smooth motion, and dependable performance for demanding industrial applications. Designed with a ball screw mechanism and static waterproof protection, it ensures long-lasting durability even in harsh environments.

Key Features

- High Load Capacity (up to 3822 lbs push / 4496 lbs hold)

- IP67 Water and Dust Protection

- Ball Screw Design for Smooth, Efficient Motion

- Durable Stainless Steel Shaft and Metal Gears

- Manual Override Function for Power Loss Situations

- Electrical Overload Protection (25A)

Request Custom Specs

Application

Tracteurs et véhicules agricoles

Les actionneurs linéaires permettent un contrôle précis de divers systèmes des véhicules agricoles, garantissant des mouvements efficaces et précis. Cette précision améliore le fonctionnement global des tracteurs et des équipements agricoles, facilitant ainsi l'exécution fluide de diverses tâches agricoles.

Défis

Les actionneurs linéaires électriques des tracteurs et des véhicules agricoles sont confrontés à des problèmes tels que la précision du contrôle, la durabilité, la capacité de charge élevée, l'efficacité énergétique, le bruit et les vibrations, la sécurité et la compatibilité avec les systèmes existants. Ces défis peuvent affecter les performances, la fiabilité et le confort de l'opérateur.

Solutions

Pour relever ces défis, utilisez des systèmes de rétroaction haute résolution, des matériaux résistants à la corrosion, une construction robuste, des moteurs économes en énergie, des mécanismes d'amortissement des vibrations, des dispositifs de sécurité et assurez la compatibilité avec les protocoles de communication standard. Un entretien régulier et des tests rigoureux améliorent encore la durabilité et la fiabilité.

Avantages

Les actionneurs linéaires améliorent les tracteurs et les véhicules agricoles grâce à un contrôle précis des mouvements, un réglage multidirectionnel et des mécanismes de sécurité avancés. Ils automatisent les tâches, améliorent la productivité, supportent des charges élevées et nécessitent peu d'entretien. De plus, ils offrent une efficacité énergétique, un fonctionnement silencieux, des systèmes de rétroaction avancés et une intégration polyvalente avec les systèmes de contrôle modernes.

Tracteurs et véhicules agricoles

Trappe de toit automatisée

Modèle

Actionneur linéaire PA-01

Fonction

Les actionneurs permettent un positionnement réglable de la trappe de toit selon différents angles.

Avantages

Les utilisateurs peuvent régler l’angle du toit en fonction de leurs préférences ou des conditions environnementales pour une ventilation optimale, une régulation de la température et une lumière naturelle.

Actionneur linéaire PA-01

De taille compacte avec des capacités de force moyennes, l'actionneur linéaire PA-01 a une faible consommation de courant idéale pour l'efficacité énergétique.

Caractéristiques principales

- Personnalisations du capteur à effet Hall

- Taille compacte

- Rapport performance/taille élevé

- Sans entretien

- Faible bruit

- Protection contre l'eau IP65

Tracteurs et véhicules agricoles

Réglages de la cabine et des sièges

Modèle

Actionneur linéaire PA-13

Fonction

Les actionneurs linéaires permettent un réglage fluide et précis de la hauteur du siège de la cabine.

Avantages

Permet aux utilisateurs d'ajuster confortablement la position assise selon leurs préférences personnelles, améliorant ainsi la commodité et l'ergonomie.

Actionneur linéaire PA-13

L'actionneur linéaire industriel haute force PA-13 est l'une des unités les plus puissantes de notre gamme.

Caractéristiques principales

- Capacité de charge élevée

- Caractéristiques de protection/sécurité

- Sans entretien

- Construction durable

- Protection contre l'eau IP66

Tractors & Farm Vehicles

Cabin and Seat Adjustments

Model

PA-HD3 Ultra High Force Industrial Linear Actuator

Function

Linear actuators allow for smooth and precise adjustment of the cabin seat's height.

Benefits

Allows users to comfortably adjust the sitting position according to their personal preference, enhancing convenience and ergonomics.

PA-HD3 Ultra High Force Industrial Linear Actuator

The PA-HD3 Ultra High Force Industrial Linear Actuator delivers powerful force, smooth motion, and dependable performance for demanding industrial applications. Designed with a ball screw mechanism and static waterproof protection, it ensures long-lasting durability even in harsh environments.

Key Features

- High Load Capacity (up to 3822 lbs push / 4496 lbs hold)

- IP67 Water and Dust Protection

- Ball Screw Design for Smooth, Efficient Motion

- Durable Stainless Steel Shaft and Metal Gears

- Manual Override Function for Power Loss Situations

- Electrical Overload Protection (25A)

Demander des spécifications personnalisées

Demander des spécifications personnalisées

Request Custom Specs

Application

Andaineurs

Les actionneurs linéaires électriques optimisent les andaineurs en ajustant la hauteur de coupe, en contrôlant la vitesse du rabatteur et en gérant la formation des andains. Cette intégration améliore la fiabilité opérationnelle, réduit les interventions manuelles et assure une répartition homogène des cultures, favorisant ainsi des pratiques agricoles plus sûres et plus efficaces.

Défis

Les défis courants auxquels sont confrontées les andaineuses agricoles utilisant des actionneurs linéaires électriques comprennent l'exposition à l'humidité, la manutention de charges lourdes, les températures extrêmes, les vibrations et les chocs, ainsi que les exigences d'alimentation électrique.

Solutions

Pour relever ces défis, des matériaux résistants à l'humidité, des composants haute résistance, des systèmes de gestion thermique avancés, des configurations de montage résilientes et des systèmes d'alimentation redondants sont utilisés. Ces solutions garantissent une durée de vie prolongée, des performances constantes et un fonctionnement ininterrompu des actionneurs linéaires électriques des andaineuses agricoles.

Avantages

Les actionneurs linéaires électriques améliorent les andaineurs agricoles grâce à un contrôle précis, une automatisation, des fonctions de sécurité, une fiabilité, une efficacité énergétique et une maintenance réduite. Ces avantages garantissent une hauteur de coupe et une formation d'andains constantes, augmentent l'efficacité opérationnelle, renforcent la sécurité de l'opérateur et réduisent l'impact environnemental et les coûts d'exploitation.

Andaineurs

Réglage de la hauteur de coupe

Modèle

Actionneur linéaire PA-13

Fonction

Les actionneurs linéaires électriques régulent avec précision la hauteur de coupe, garantissant une coupe de récolte uniforme et précise.

Avantages

Optimisant la qualité des récoltes et maximisant le rendement, le réglage précis de la hauteur de coupe améliore l'efficacité de la récolte en garantissant une hauteur uniforme sur l'ensemble des champs. Cette uniformité minimise le gaspillage et améliore la productivité globale de l'exploitation.

Actionneur linéaire PA-13

L'actionneur linéaire industriel haute force PA-13 est l'une des unités les plus puissantes de notre gamme.

Caractéristiques principales

- Capacité de charge élevée

- Caractéristiques de protection/sécurité

- Sans entretien

- Construction durable

- Protection contre l'eau IP66

Demander des spécifications personnalisées

Application

Épandeurs

Les actionneurs linéaires électriques jouent un rôle essentiel dans les épandeurs agricoles en permettant un contrôle précis des débits de distribution, garantissant ainsi une application uniforme dans les champs. Leur intégration automatise les fonctions clés et intègre des dispositifs de sécurité avancés, améliorant ainsi l'efficacité opérationnelle et la sécurité des pratiques agricoles.

Défis

Relever les défis des épandeurs agricoles utilisant des actionneurs linéaires électriques implique de garantir la durabilité contre la pénétration de poussière et de débris, la corrosion due à l'exposition à l'humidité, la manipulation de charges lourdes, la résistance aux températures extrêmes, l'atténuation des vibrations et des chocs, la garantie de la fiabilité de l'alimentation électrique, le maintien de la précision et de l'exactitude, l'intégration transparente avec les systèmes de contrôle, l'optimisation de l'efficacité énergétique et la minimisation de la maintenance et des temps d'arrêt.

Solutions

Les solutions aux défis des épandeurs agricoles équipés d'actionneurs linéaires électriques comprennent des conceptions étanches avec un indice de protection IP élevé pour empêcher la pénétration de poussière et de débris, ainsi qu'une protection contre l'humidité. Une construction robuste pour les charges lourdes, des composants résistants aux températures élevées, des mécanismes d'amortissement, des solutions d'alimentation de secours, des capteurs de haute précision pour une précision optimale, des protocoles de communication standardisés pour l'intégration, des conceptions écoénergétiques et des fonctions de maintenance prédictive pour des temps d'arrêt minimaux.

Avantages

Les actionneurs linéaires électriques offrent un contrôle précis, une automatisation, des fonctions de sécurité, une fiabilité, une efficacité énergétique, une maintenance réduite et un fonctionnement silencieux pour les épandeurs agricoles. Ils garantissent des débits de distribution constants, réduisent les interventions manuelles, améliorent la sécurité de l'opérateur, optimisent les performances, réduisent les coûts d'exploitation, prolongent la durée de vie et minimisent les nuisances sonores, contribuant ainsi à améliorer la productivité et la durabilité des exploitations agricoles.

Épandeurs

Gestion des portes de trémie

Modèle

Actionneur linéaire PA-09

Fonction

Les actionneurs linéaires électriques contrôlent avec précision le flux de matériau en ouvrant et en fermant la porte de la trémie à des endroits précis.

Avantages

Améliore l'efficacité de l'épandage en évitant les chevauchements ou les zones manquées, et la gestion précise des portes de la trémie garantit un fonctionnement fluide et constant. Cela renforce l'intégrité du processus d'épandage, optimise la distribution des matériaux et minimise le gaspillage des ressources.

Actionneur linéaire PA-09

Le PA-09 offre une durabilité et des capacités de force élevées dans un actionneur linéaire de taille compacte.

Caractéristiques principales

- Taille compacte

- Faible bruit

- Force élevée

- Sans entretien

- Excellent rapport qualité/prix

Demander des spécifications personnalisées

Application

Matériel de semis

Les actionneurs linéaires électriques optimisent les équipements de semis en contrôlant avec précision le placement, la profondeur et l'espacement des graines. Leur intégration simplifie les opérations, réduit les réglages manuels et assure une levée uniforme des cultures, favorisant ainsi des pratiques agricoles plus sûres et plus efficaces.

Défis

La résolution des problèmes liés aux équipements de semis utilisant des actionneurs linéaires électriques implique divers obstacles techniques tels que la pénétration de poussière et de débris, l'exposition à l'humidité, la manutention de charges lourdes, les températures extrêmes, la fiabilité de l'alimentation électrique, les vibrations et les chocs, la précision des commandes et l'efficacité énergétique. Chaque défi nécessite des solutions rigoureuses pour garantir un fonctionnement optimal et une longue durée de vie en milieu agricole.

Solutions

Les solutions incluent des conceptions étanches avec des indices IP élevés pour empêcher la pénétration de débris et d'humidité, des matériaux résistants à la corrosion pour une longévité accrue, une construction robuste pour les charges lourdes et des matériaux résistants aux températures élevées. Une alimentation électrique stable, des mécanismes d'absorption des chocs, des systèmes de rétroaction haute résolution et des conceptions écoénergétiques optimisent les performances en milieu agricole.

Avantages

Les actionneurs linéaires électriques offrent un contrôle précis, une automatisation et une sécurité optimales pour les équipements de semis agricoles. Ils assurent un placement régulier des semences, augmentent l'efficacité opérationnelle et renforcent la sécurité de l'opérateur. Grâce à des capteurs avancés, ils assurent une surveillance en temps réel, réduisent la consommation d'énergie, nécessitent moins d'entretien et fonctionnent silencieusement, au bénéfice des opérateurs et du bétail.

Matériel de semis

Réglage du placement des graines

Modèle

Actionneur linéaire PA-13

Fonction

Les actionneurs linéaires électriques ajustent le positionnement de l'équipement de semis pour réguler avec précision le placement des graines.

Avantages

Assure un espacement constant et optimal des semences, améliorant le rendement des cultures en favorisant une croissance uniforme des plantes et en réduisant la concurrence entre les plantes pour les ressources.

Actionneur linéaire PA-13

L'actionneur linéaire industriel haute force PA-13 est l'une des unités les plus puissantes de notre gamme.

Caractéristiques principales

- Capacité de charge élevée

- Caractéristiques de protection/sécurité

- Sans entretien

- Construction durable

- Protection contre l'eau IP66

Demander des spécifications personnalisées

Application

AgTech et automatisation

Les actionneurs linéaires électriques sont essentiels dans l'agriculture verticale, permettant un contrôle précis de l'éclairage, de l'irrigation et des racks verticaux pour optimiser la croissance et le rendement des cultures.

Défis

Assurer un mouvement précis des plateaux et des étagères pour une croissance uniforme des plantes, gérer les charges lourdes, l'exposition aux conditions environnementales, la consommation d'énergie élevée, l'espace limité, l'intégration avec les systèmes d'automatisation et la maintenance fréquente perturbant les opérations.

Solutions

Mettez en œuvre des contrôleurs haute résolution, utilisez des actionneurs à haute capacité de charge, sélectionnez des matériaux robustes et résistants à la corrosion, optez pour des actionneurs économes en énergie, choisissez des conceptions compactes, assurez la compatibilité avec les protocoles industriels et sélectionnez des actionneurs nécessitant peu d'entretien.

Avantages

Les actionneurs linéaires électriques offrent un contrôle précis, automatisent les fonctions clés, améliorent l'efficacité énergétique, nécessitent peu d'entretien, garantissent la fiabilité grâce à des capteurs avancés et offrent un fonctionnement silencieux, ce qui les rend idéaux pour l'agriculture verticale.

AgTech et automatisation

Gestion des racks verticaux

Modèle

Actionneur linéaire PA-04-HS

Fonction

Les actionneurs linéaires électriques ajustent la position des supports de plantation pour faciliter l'accès et maximiser l'utilisation de l'espace.

Avantages

Améliore l'utilisation de l'espace et permet un contrôle pratique de l'opérateur pour faciliter le processus de récolte et de maintenance.

Actionneur linéaire PA-04-HS

Le PA-04 est l'actionneur linéaire le plus polyvalent de notre gamme offrant des options de rétroaction de capteur à effet Hall.

Il est populaire dans les industries des machines mobiles et de l'agriculture.

Caractéristiques principales

- Force nominale polyvalente

- Rétroaction du capteur à effet Hall

- Sans entretien

- Excellent rapport qualité/prix

- Protection contre l'eau IP66

Demander des spécifications personnalisées

Application

Cueilleurs et récolteuses de fruits

Les actionneurs linéaires électriques améliorent la fonctionnalité des machines de récolte en offrant un contrôle précis, une automatisation et des fonctions de sécurité. Leur intégration permet d'accroître la productivité et la sécurité tout en minimisant les besoins en main-d'œuvre.

Défis

Assurer la durabilité des actionneurs linéaires électriques dans les environnements difficiles de récolte de fruits, maintenir la précision et l'exactitude, les intégrer dans les systèmes existants et garantir la sécurité et la fiabilité sont des défis techniques clés pour optimiser l'efficacité des cueilleurs et des récolteuses de fruits.

Solutions

L'utilisation d'un boîtier robuste et de matériaux résistants à la corrosion garantit la durabilité des actionneurs linéaires électriques. La mise en œuvre d'actionneurs de haute précision dotés de mécanismes de rétroaction adaptés, de stratégies d'intégration transparentes et de mesures de sécurité complètes optimise les performances des cueilleurs et des récolteuses de fruits.

Avantages

Les actionneurs linéaires électriques sont privilégiés pour la cueillette et la récolte des fruits en raison de leur contrôle précis, de leurs capacités d'automatisation, de leurs fonctions de sécurité, de leur fiabilité, de leur efficacité énergétique, de leur faible maintenance et de leur fonctionnement silencieux. Ils garantissent une manipulation précise, réduisent le travail manuel, améliorent la sécurité et la fiabilité, réduisent les coûts d'exploitation et contribuent à un environnement de travail plus silencieux, optimisant ainsi les pratiques agricoles.

Actionneur linéaire résistant à l'eau IP66 - Rétroaction en option

Voir le cas d'utilisation Voir le produit

Actionneur linéaire résistant à l'eau IP66 - Rétroaction en option

Voir le cas d'utilisation Voir le produitCueilleurs et récolteurs de fruits

Réglage des mécanismes de prélèvement

Modèle

Actionneur linéaire PA-10

Fonction

Les actionneurs linéaires électriques positionnent et ajustent les mécanismes de cueillette à la hauteur et à l'angle optimaux pour la récolte des fruits.

Avantages

Convient à différents types de fruits poussant à différentes hauteurs et orientations. Garantit un alignement correct des outils de cueillette, minimisant ainsi les dommages aux fruits et à la plante.

Actionneur linéaire PA-10

Le PA-10 est un actionneur étanche hautement efficace conçu pour une large gamme d'applications, y compris les équipements agricoles.

Caractéristiques principales

- Personnalisations du capteur à effet Hall

- Taille compacte

- Rapport performance/taille élevé

- Sans entretien

- Faible bruit

- Protection étanche IP68M